Polyurea Coatings: Durable, long lasting protection

Maybe you’re looking for added protection for your assets, and you’ve come across something called polyurea. You might be wondering if it would work for your application. But what exactly is it?

First of all, polyurea coating technology combines remarkable protection with a vast range of uses. However, as with any coating system, there are steps to follow for success. Proper surface preparation, correct application equipment, and the use of compatible primers are required. Once these conditions are met, it outperforms other options. And in many cases, it is the most durable, longest lasting option available, as well.

- Multiple markets around the globe successfully use polyurea.

- It is more durable than paint. Additionally, it lasts longer between maintenance cycles.

- Polyurea is the best choice when it comes to cost/performance payback and operation.

Benefits of Polyurea

If you were making a list of the best protective coatings available, at or near the top of the list would be polyurea. As coating technologies go, it’s a relative newcomer — just over 30 years since initial development. However, in that time it has proven itself to be one of the most capable options on the market. It is a two-part system, made from by-products of the petroleum industry. Those two components combine to form a completely inert, extremely durable membrane. Polyurea is environmentally friendly, and contains no VOCs, making it one of the greenest coating systems that exist.

Caribbean Coatings uses only the highest quality polyurea coatings for their projects, sourced directly from industry leading manufacturers. Our contractors determine the correct system for every application. If you have a difficult set of conditions on your job, let us help you find the right solution.

Tropical conditions make installation of traditional coating systems difficult. High daytime temperatures, excessive humidity, and frequent rainfall cause delays in even the best laid construction plans. These conditions make polyurea an excellent choice. It cures nearly instantly, typically in less than 20 seconds. Additionally, it sprays in high build thickness in a single pass. Often, assets return to service in less than one hour. Try that with an epoxy coating!

To read more about the solutions we offer, visit our sister website: polyureasystems.com.

Polyurea vs Other Coatings: the Shootout

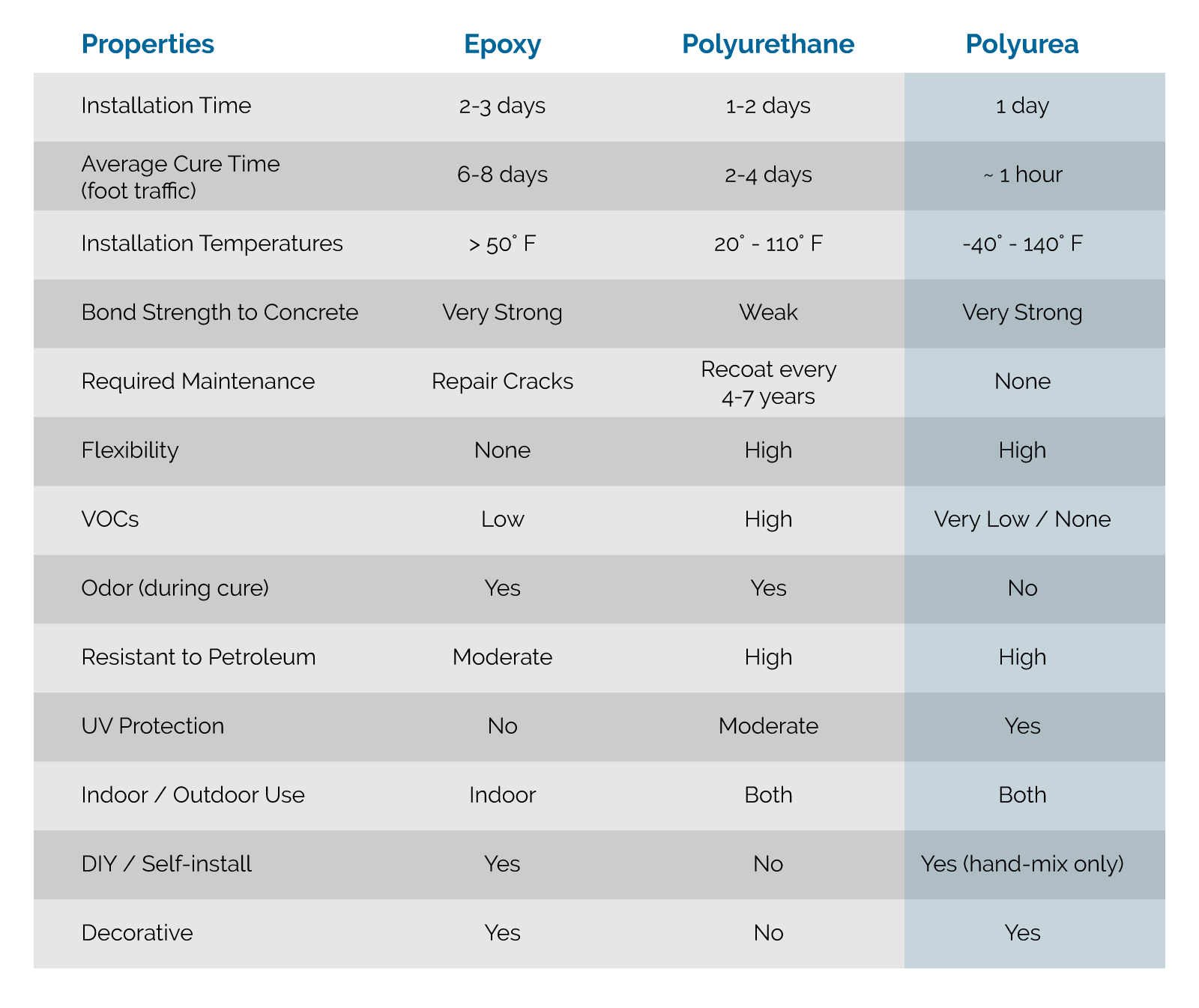

Some people claim that traditional protective coatings are tried and true, so why try some newfangled coating? And of course, there is definitely something to be said for going with the devil you know. However, a side-by-side comparison chart of how polyurea technology measures up to epoxy and polyurethane coatings helps to clarify the benefits of using polyurea technology over the others.

One main thing to consider is how polyurea installs versus epoxy or polyurethane. Both of the more traditional systems often take days or even weeks to finish curing. Additionally, epoxy and polyurethane are more finicky when it comes to moisture and temperature conditions during install. Polyurea doesn’t have the same problems, making it the clear choice for ease of install.

Another important point to keep in mind is maintenance costs. With polyurea, there is basically none required beyond washing to remove any grime or build-up that may accrue over time. And that’s not even actually required, it just makes it look nicer.

On the other hand, both epoxy and polyurethane will definitely require maintenance, which may include downtime to perform.

For epoxies, repairing cracks is probably going to be the main issue, and that can be difficult to do well.

For polyurethanes, you will have to recoat every 4-7 years depending on various factors – although the main reason is the weak bond strength to the substrate.

Polyurea benefits? Bottom line.

As shown by the graph above, polyurea outshines traditional coatings in many ways.

Less time for install and full cure.

Polyurea is the obvious winner when it comes to install & cure times. Being able to walk on the coating within hours allows us to rapidly apply full jobs, and perform cut-ins and touch-ups before the day is done. This also means that you’re back up and running in less time than with any other coating options.

Installation conditions matter less.

With epoxy coatings, install temperatures have to be (and remain) above 50° F for the duration of the install and cure process. With polyurethane coatings, the install temperature range is wider, but multiple applications may be needed to reach a desired or specified thickness.

Polyurea, on the other hand, can be installed at temperatures you wouldn’t even want to be in for any length of time. Of course, this makes it perfect for cold or hot weather installs. And since polyurea is a high-build coating, fewer passes are needed to achieve a given thickness.

You can finally be maintenance-free.

Ongoing maintenance costs? With epoxy and polyurethane, yes, and possibly they may require a full recoat (polyurethane will, for sure). However, with polyurea it’s going to be right around that zero mark for maintenance costs, making it much more appealing in the long run.

And truthfully, when adding up lifetime costs of the various systems, the initial investment may be nominally higher for polyurea but in the end it more than evens out in polyurea’s favor when considering extended downtime for maintenance and repairs necessary with epoxies and polyurethanes.

Flexibility and longevity

When applying a protective coating to a substrate like concrete, it’s easy to think that the concrete is always stable, and won’t ever move. However, that’s rarely ever the case, as concrete continues to cure over the course of its life and slowly contracts. And of course, because concrete is terrible in tension, any ground movement has the potential to cause structural damage. Ultimately, any protective coating applied will need to be able to accommodate this type of movement to some degree.

Polyurea is much more flexible than epoxy and polyurethane, and can often handle all but major structural dislocations. In fact, because the bond strength to concrete is so high, often concrete will fail internally before the polyurea coating will let go. If you’re looking for a way to extend the usable life of your infrastructure, a polyurea coating might be the right fit

POLYUREA OVER CONCRETE